Research of Testa Tower

One of my final projects included a forensic study of the Carbon Tower designed by Peter Testa and Devyn Weiser. This was almost purely a research project, starting with what is available about the building today and working backwards in order to imagine how the unbuilt project could be brought from concept to real life.

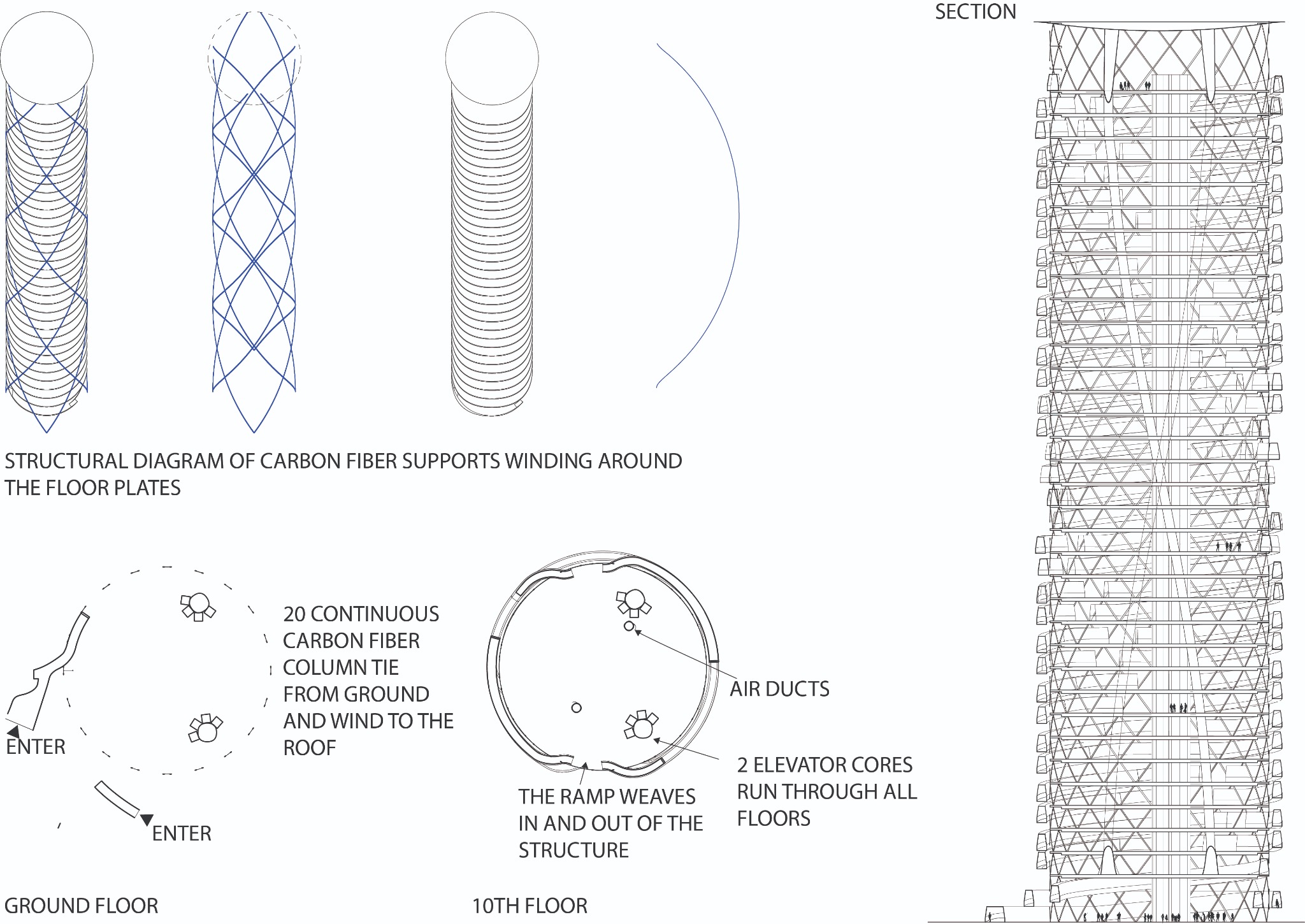

Testa Tower Structure

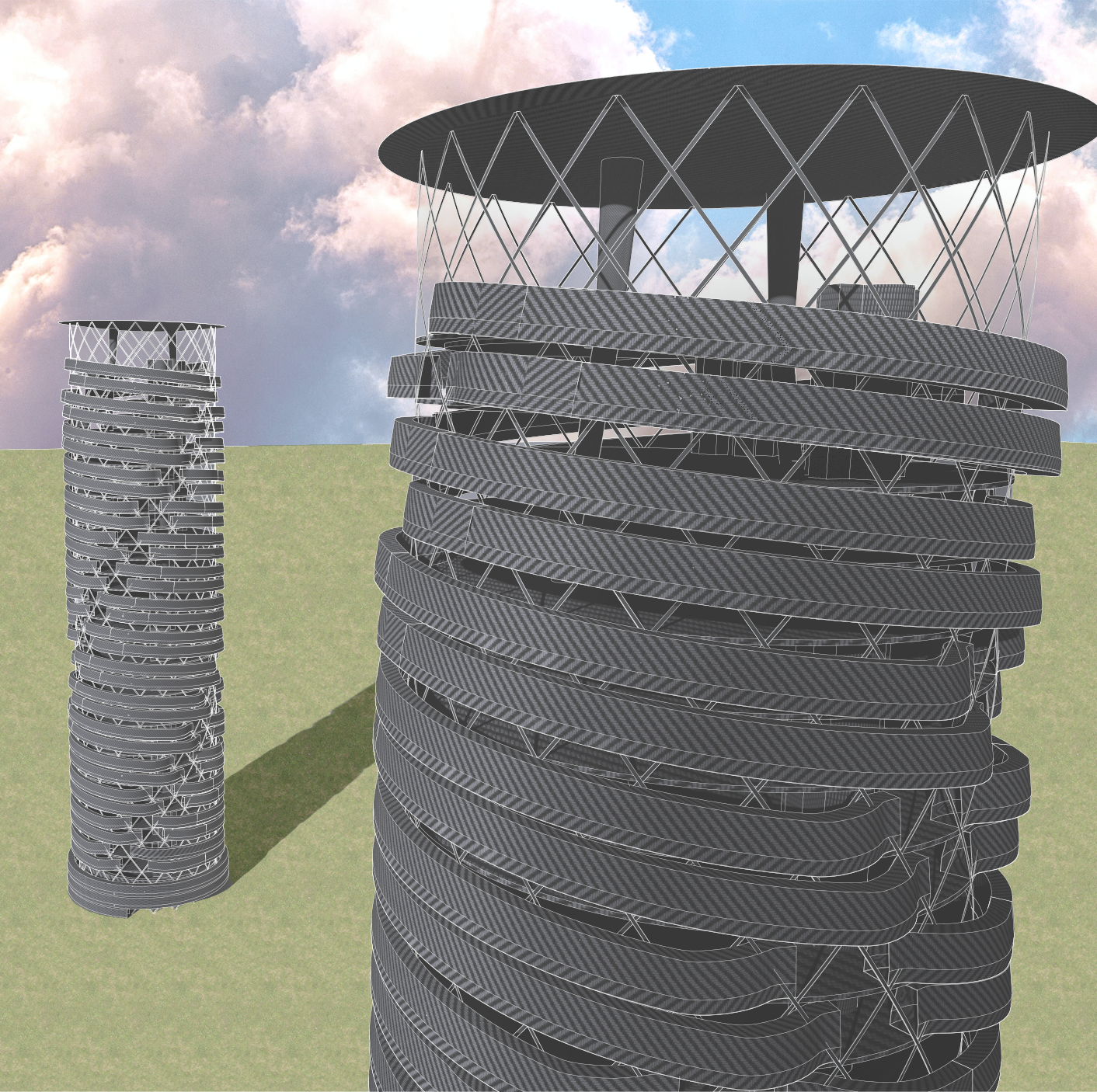

To begin with I studied the structure and compiled as much data as I could about the tower. It was designed alongside a software that helped create it. The basic idea of the structure was that this helical bundles of carbon fibers would wind up a structure and floor plates would hang from it. This proved to lead to fascinating dives into how it could potentially be constructed, the machines that would be involved in building it, and how the carbon fiber worked in this process.

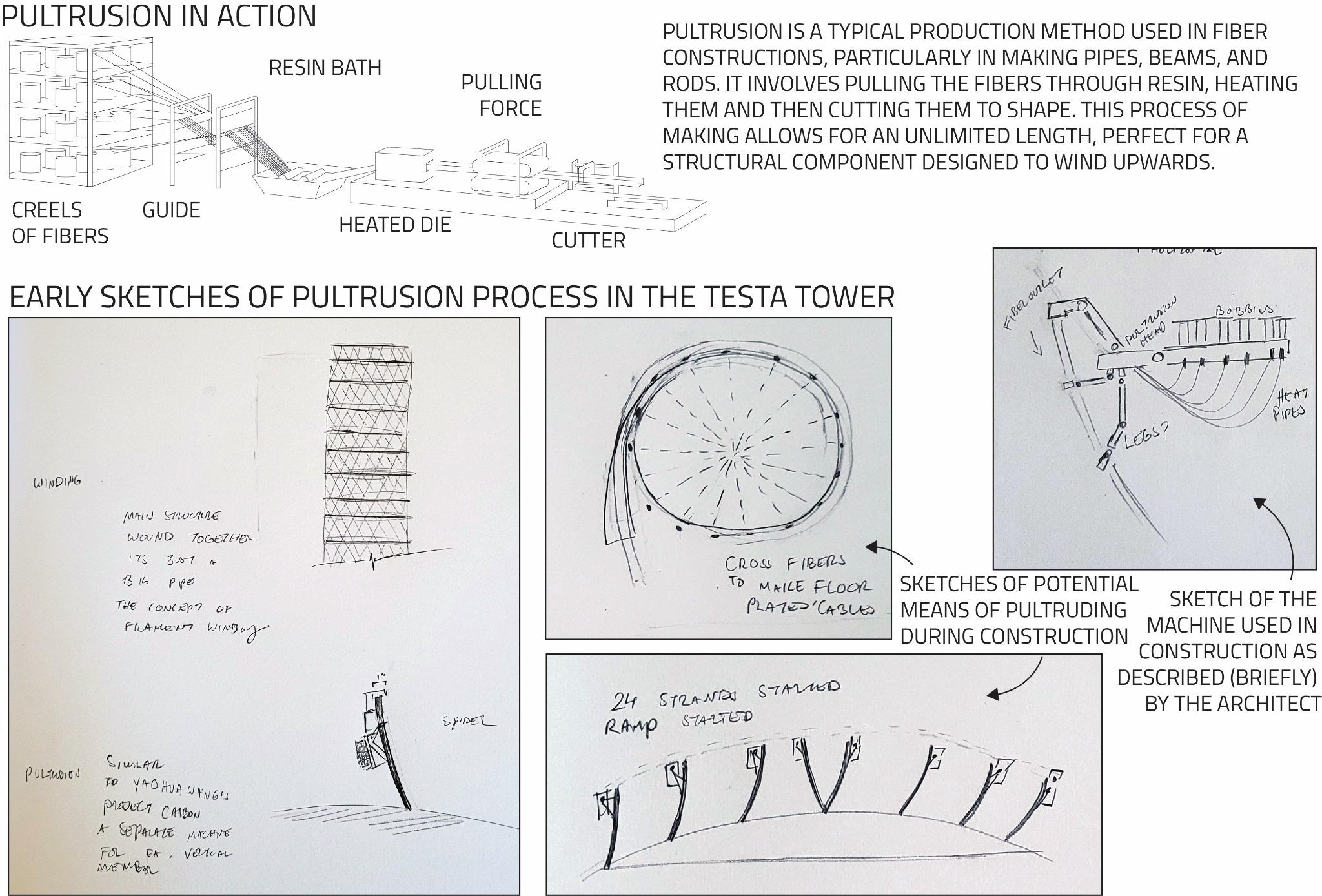

The first study into this process involved understanding carbon fiber as a building material. It's not a common building material right now due to the expense, but it is often used in making machine parts (think especially automotive and aerospace) so there are already a variety of techniques out there in building.

After conducting my own interview at a carbon fiber facility, I came to the following conclusions about the different means of production that could be potentially used specifically for the Testa Tower.

Construction Process

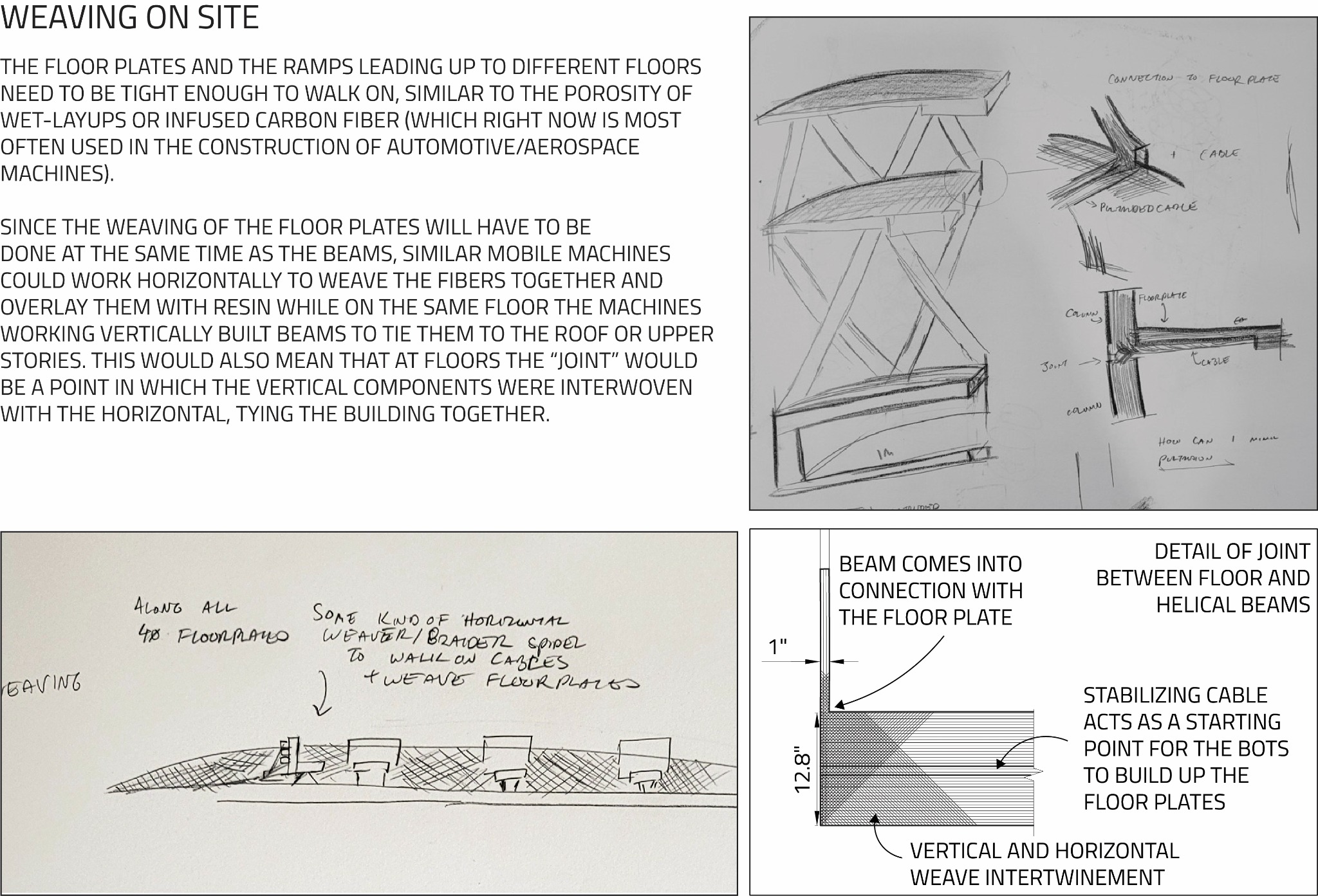

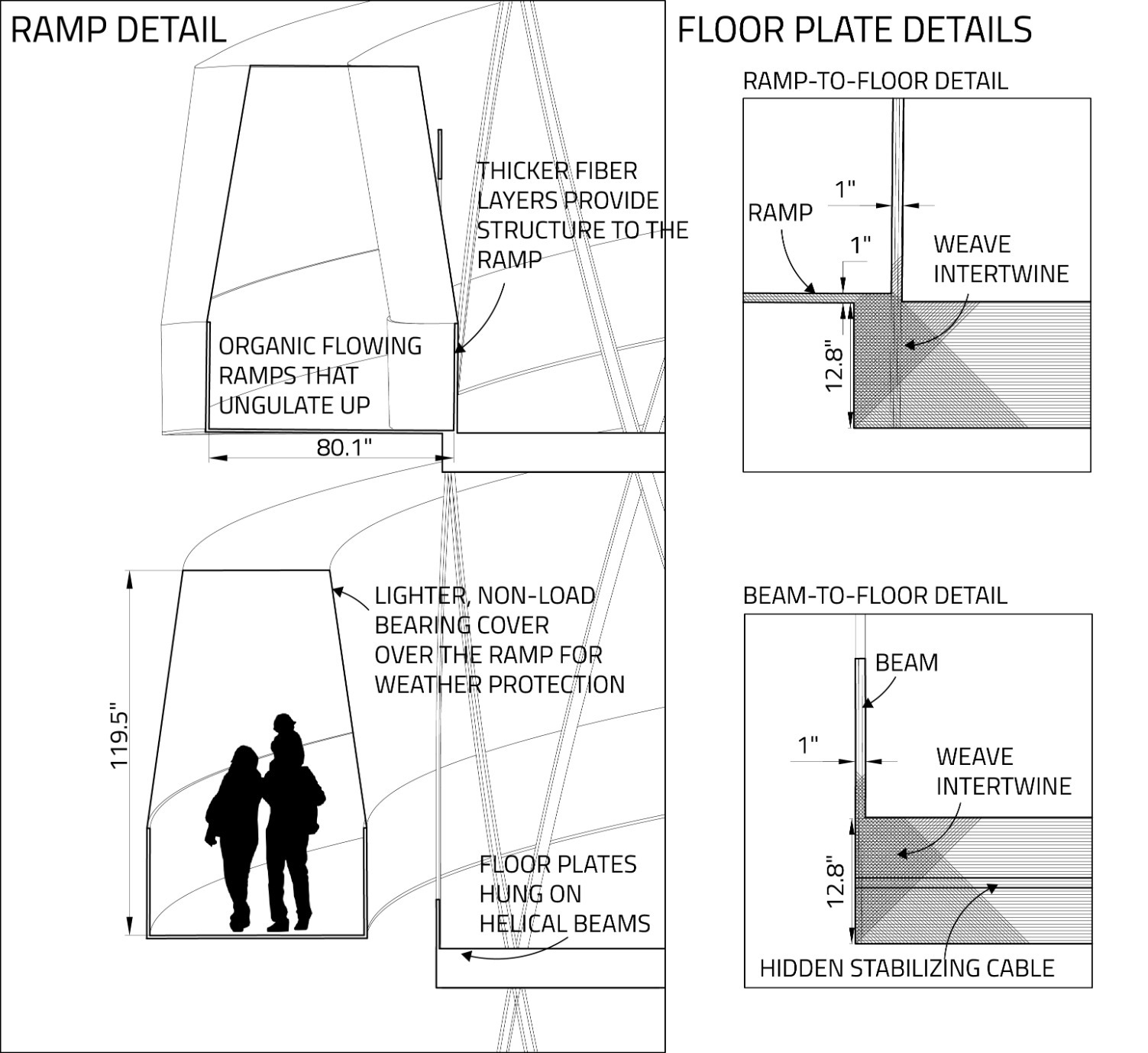

My research revolved around a couple ideas pertaining to the construction of Testa Tower. The first idea was that the project could be woven entirely on-site, there would be no transporting large blocks of finished building pieces. The only thing to be transported would be the fibers, resin, and machines to build it. The second was to take advantage of gravity in constructing the project. Carbon fiber is incredibly strong, but also incredibly light. The idea would be that floor plates would be hung from the beams, so in theory you could begin the process of construction utilizing the cores and beams to stabilize and build down from the top, aiding the pultrusion process.

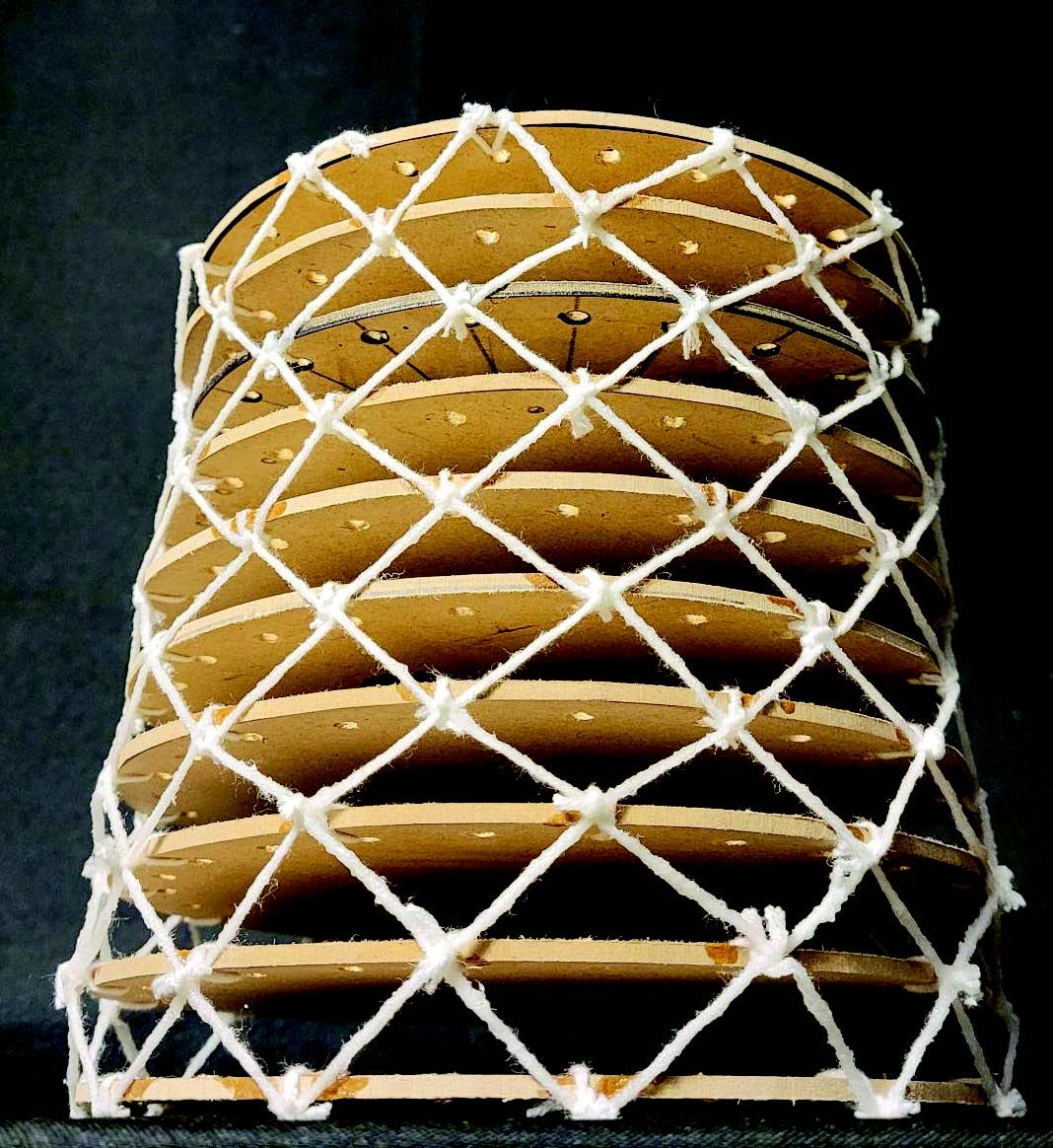

On a small side note, it was interesting to consider building both up and down. I could understand how easy it was to emply gravity in this case through a simple model experiment. The above image is my attempt at building the helix pattern up, first holding the floor plates directly above it and applying glue to thread to get a smaller but similar experience to resin over fiber. It warped instantly and was difficult to keep aligned. The project on the right however, was built hanging it down, a much simpler process!

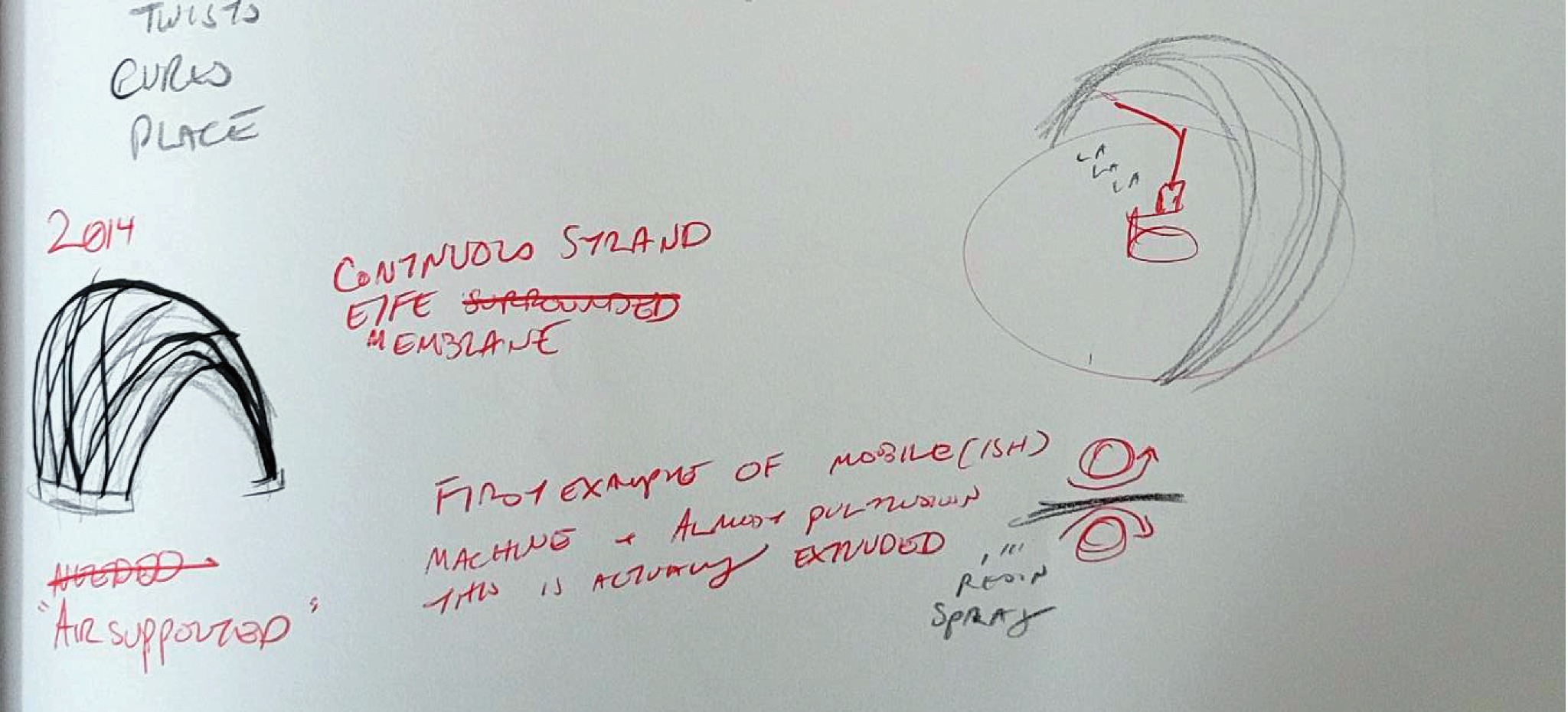

Throughout this project which is entirely based off a precedent, there were many other precedents that became essential to proving the effectiveness of using carbon fiber for structural purposes. Stuttgart University's series of ITKE Pavilions became critical for developing ideas as to what the machines used to build the structure would look like as well as visualize the processes of building.

Their ITKE Research Pavilion 2014-15 (which my sketch represents), as well as 2013-2014 became a great inspiration in considering the process of pultrusion.

The actual construction process is then imagined. All that needs to be then considered is who is doing the buildings.

Peter Testa very briefly touched on an idea of spider robots that somehow wove the project together both horizontally and vertically at the same time. It's easy to imagine small machines that contain rollers or vacuums to move in one direction along a bundle of fibers could cling strong enough to continue a weave, moving down or horizontally. All that remains is to lower the cost of carbon fiber and composite materials!